Metal Fabrications - Welding and Pem Insertion

Pro Metal Works offers an extensive array of methods for fastening metal parts together - operated by outstanding professionals. These methods are welding, pemming, spot welding, and Tog-L-Loc. Our staff is well trained and certified to AWS D1.1, D1.2, and D1.3 welding standards. When you need help welding or fastening together light gauge metal turn to us for all of your needs. See below for further details.

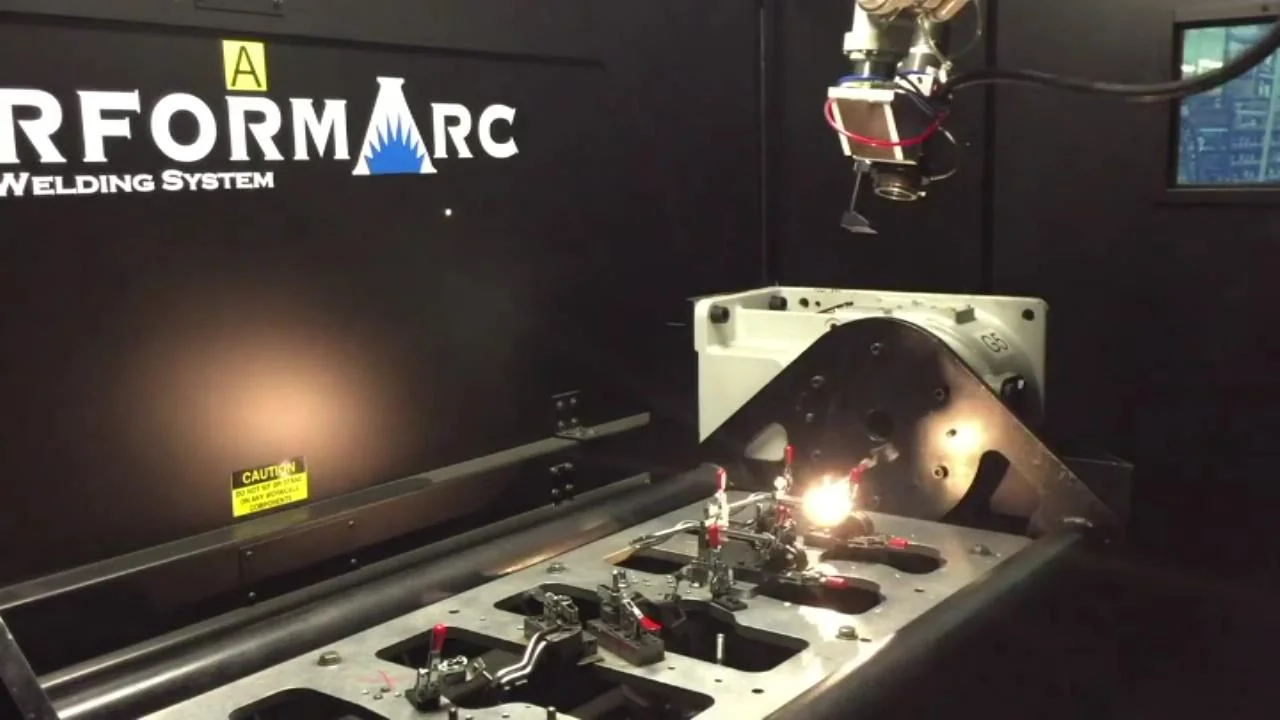

Miller PA-1100HW PerformArc fiber laser welding robot cell

The Performarc laser welding cell is latest generation in a new and expanding technology using a fiber laser resonator mounted to a robotic welding cell. The result is a technology way beyond what is used by most conventional manufacturers. Here is a list of it's attributes and benefits:

Minimal heat into the part drastically minimizing distortion and increasing handling time.

The beam is narrow and precise with an excellent depth-to-width ratio resulting in higher strength welds.

Drastically increased speed of nearly 10x that of conventional welding robots.

Able to reach into tight locations because it only relies on line of sight for welding. There is no need for the laser head to be in contact with the part, it welds from 20" away.

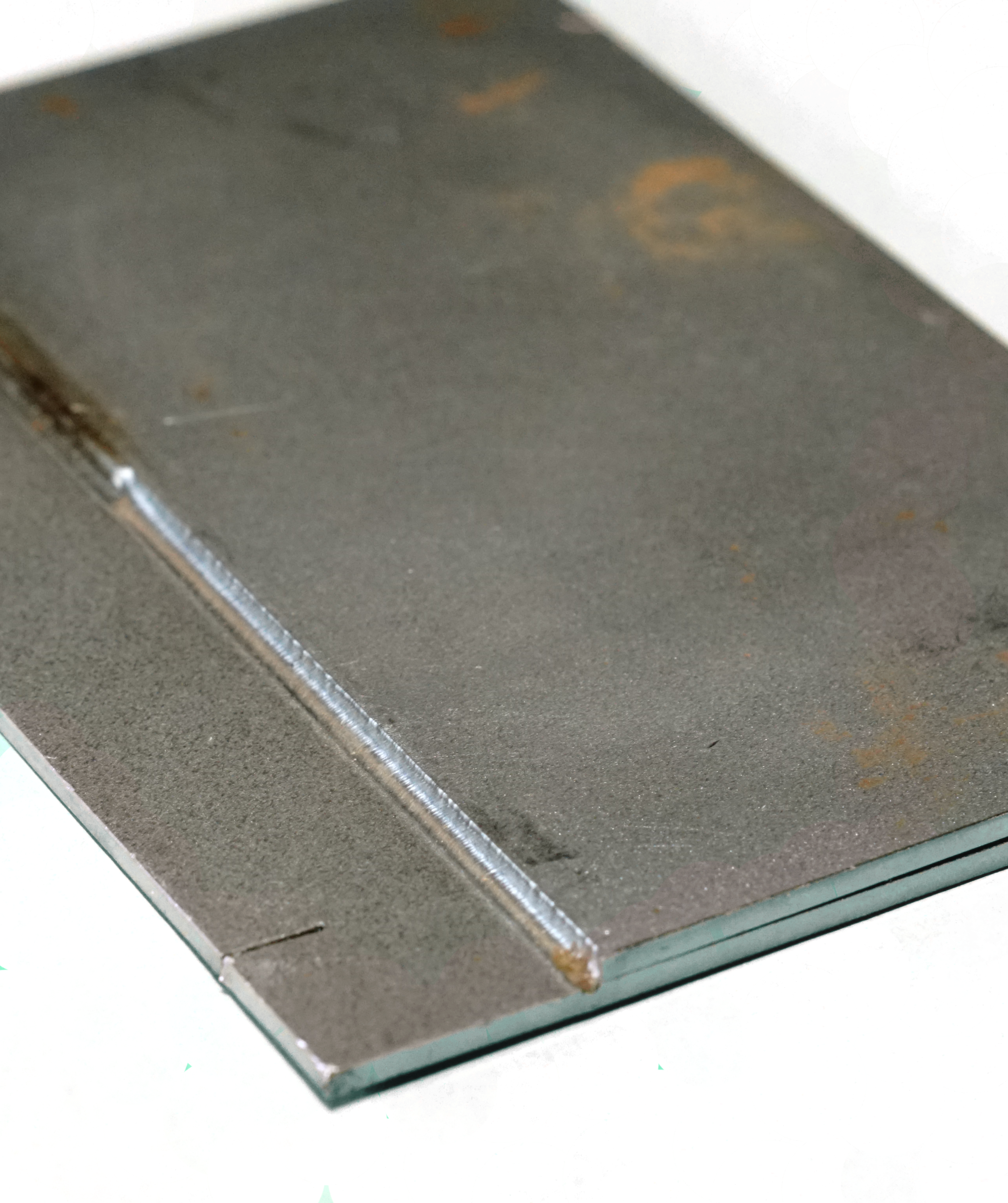

LASER WELDING SAMPLE

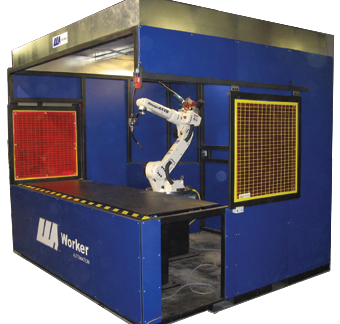

worker automation ARcworker dst series welding robot cell

The Dual Stationary Table system allows for larger parts to be welded. The operator can prepare the work on side A while the robot is welding on side B. The simultaneous loading & welding provides a 50% increase in productivity over manual operations

Work piece window 30" x 40"

Maximum weight of 100lbs

6 axis 55" reach

120" bed

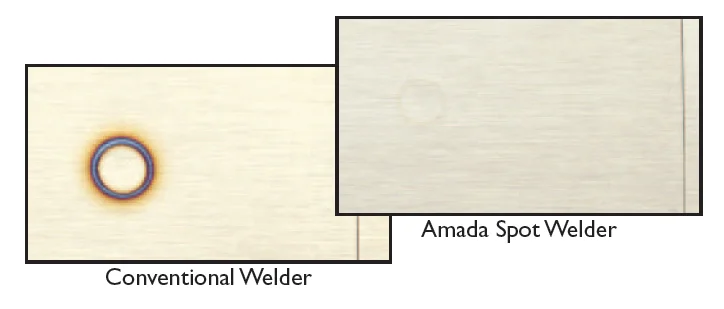

AMADA ID40IV ST Spot Welder

The ID40IV STProvides Class A welding performance across a wide range of material by consistently delivering stable direct current output, resulting in superior finished products that require little or no post processing.

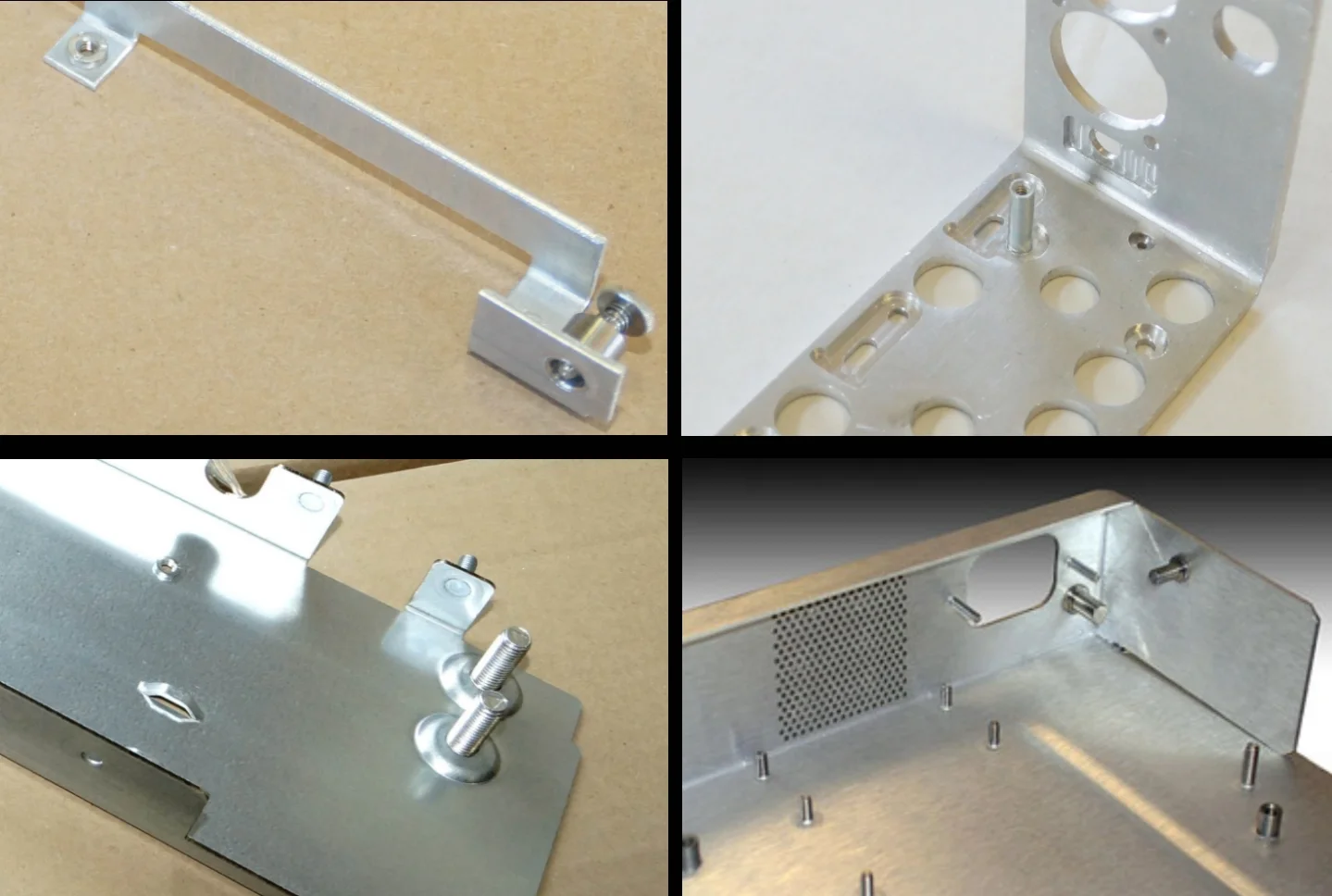

Haeger 824 one touch

The 824 is a versatile machine for inserting four different fasteners in a single part handling. This reduces part handling and cuts down on work-in-progress.

Haeger 824 with Tog-l-loc tooling

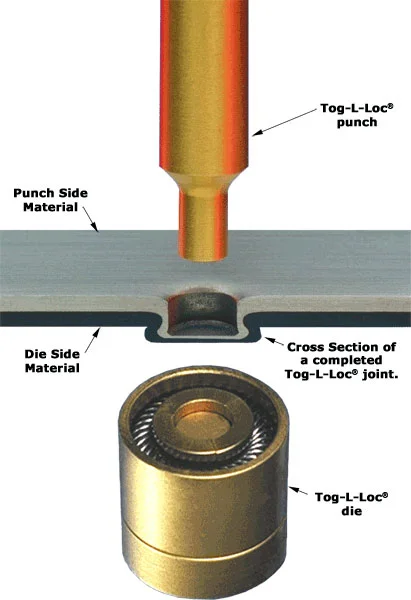

Tog-L-Loc® is a process known as clinching which cold-forms a metal part using a special punch and die to form a strong interlocking clinch joint. The result of the process is a round, button shaped extrusion on the die side of the assembly, and a small cylindrical cavity on the punch side. The clinch joint requires only the sheet metals that were joined. No external fasteners, or welding is utilized in the process. This is an excellent option for galvanized parts that require spot welding. Spot welding galvanized parts does give off dangerous fumes that can cause metal fume illness. Mechanically fastening parts eliminates that for a better and safer joining of parts.