Pro Metal Works is the industry leader in metal cutting technology. You would be very hard-pressed to find so much advanced technology in one single location. And because we are the leader, you're assured that we will meet your needs. Many times we are the first to use new industry technology, like being one of only a handful of companies throughout North America first to embrace Fiber Optic cutting technology. Our advanced ability to cut your parts gives you peace of mind knowing that your parts will be done on-time, to your specifications, and at a cost driven by speed and automation.

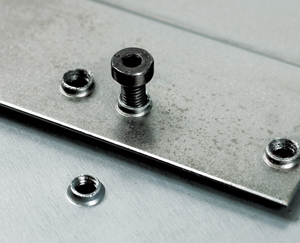

The ACIES has the ability to extrude holes then tap them, thus eliminating the need for pem inserts, weld nuts, or other various fasteners.

The ACIES has the ability to punch a countersunk hole. This gives us the benefit of eliminating a costly machining step allowing us to drive down the cost to our customers.

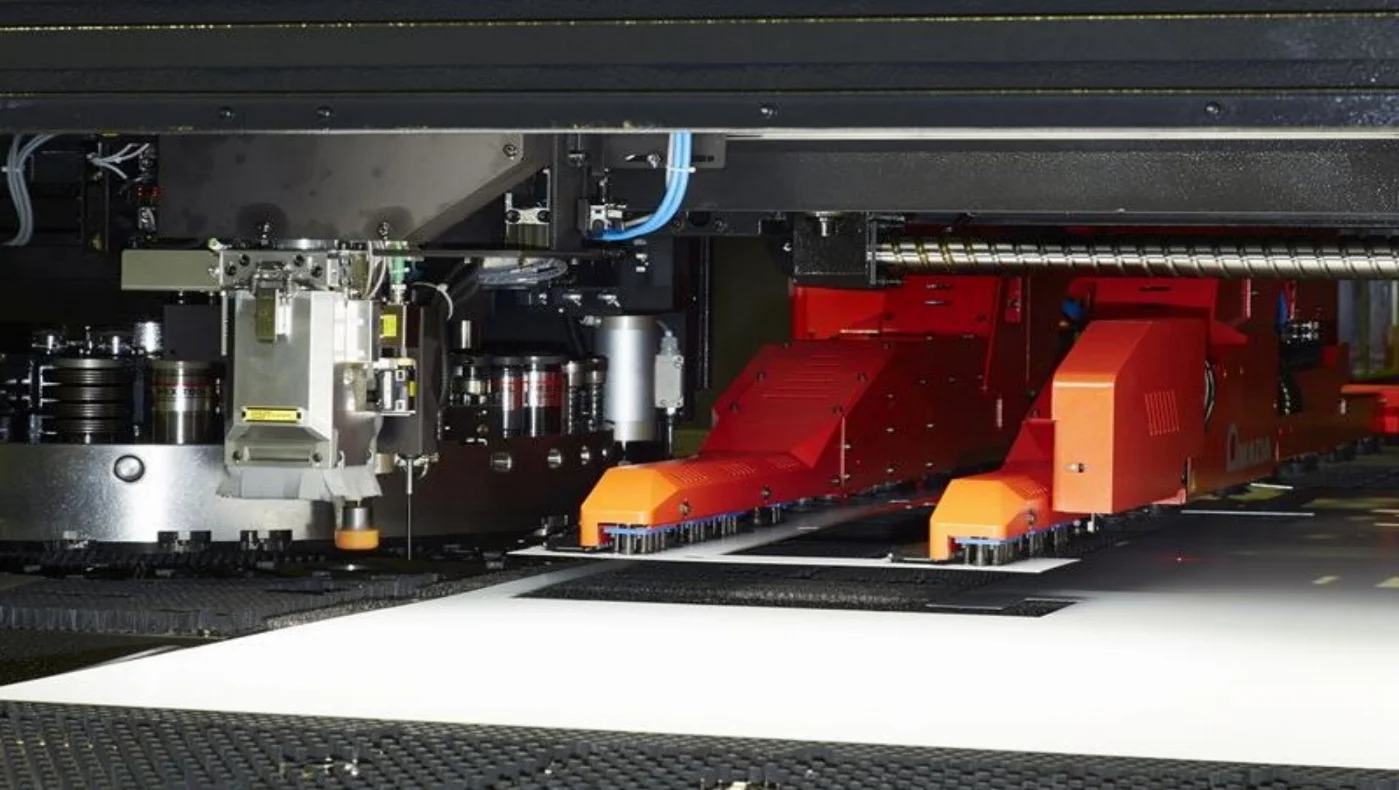

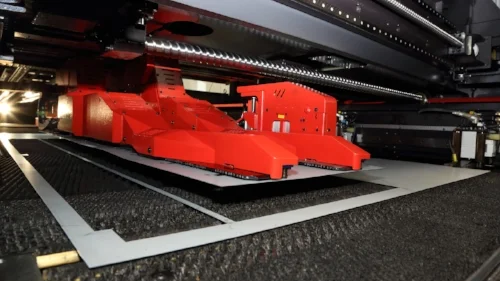

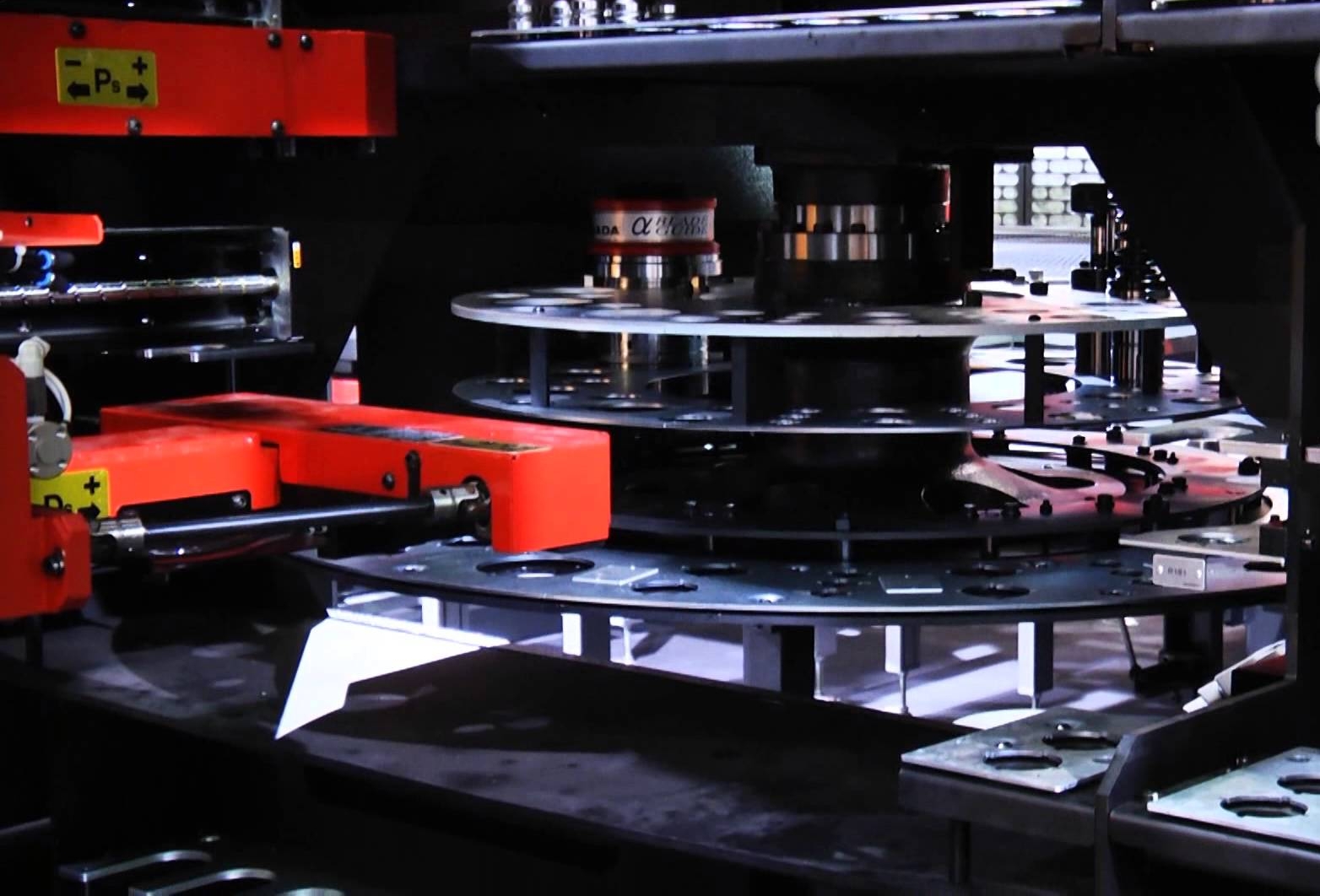

AMADA ACIES 2515T LASER/turret w/automated material handling

When you combine a laser system with a turret, you achieve unmatched performance and versatility. The Amada ACIES boasts rapid hit rates and a tooling library capable of holding 300 tools, say bye-bye to long human interactive tool setups, with an automated tooling library setups are a breeze. New technology introduced by Amada now allows form ups and form downs, and the ACIES also incorporates live tool centers for thread tapping all in one machine.

- 60 x 120 max material size

- 12ga max material thickness

- automated part picking technology

- 300 station integrated tooling storage

- automated tooling setup

- 4 station tapping tool

- ability form up and form down

- Lights out 24/7 load and unload system

AUTOMATED PART HANDLING

INTEGRATED LIVE TAPPING STATION

ROBOTIC TOOL CHANGER

300 STATION TOOLING LIBRARY

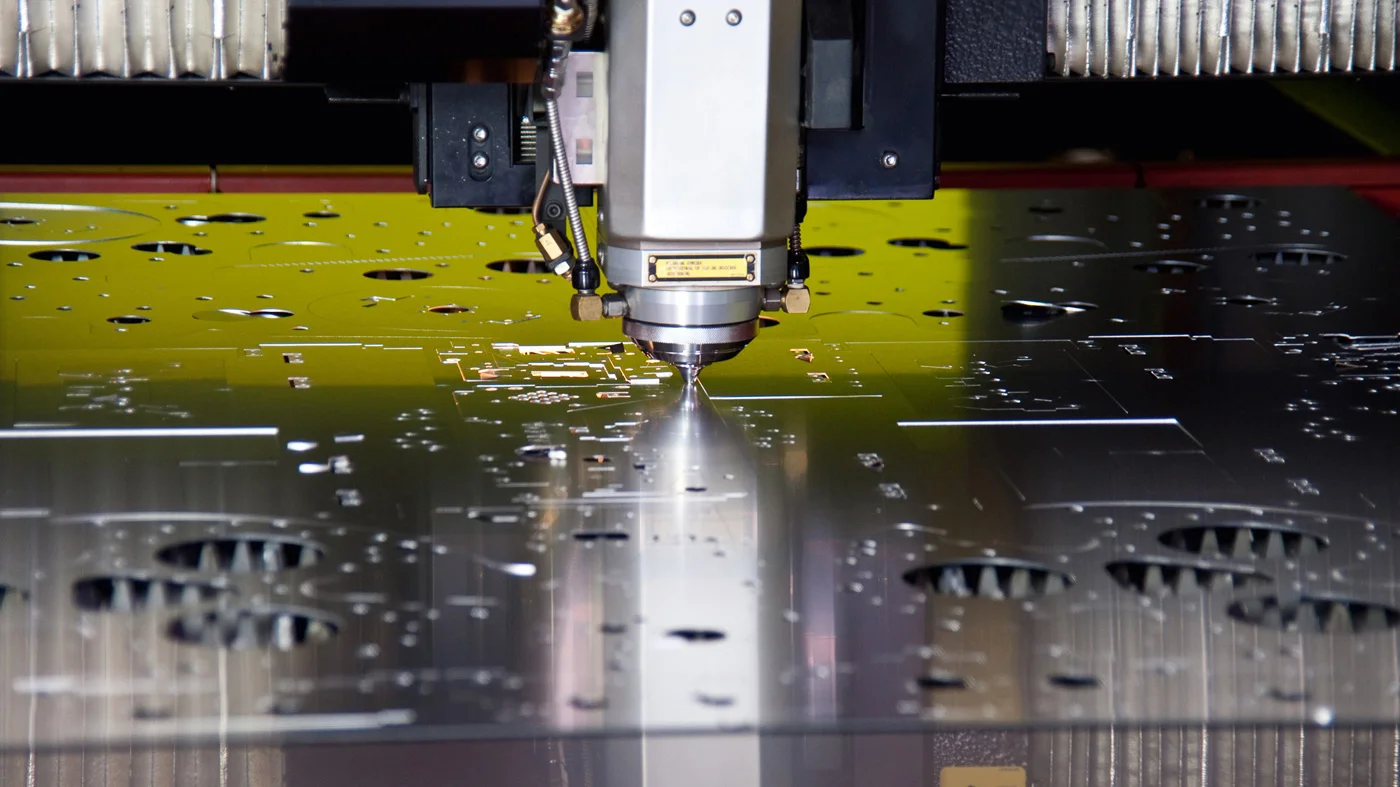

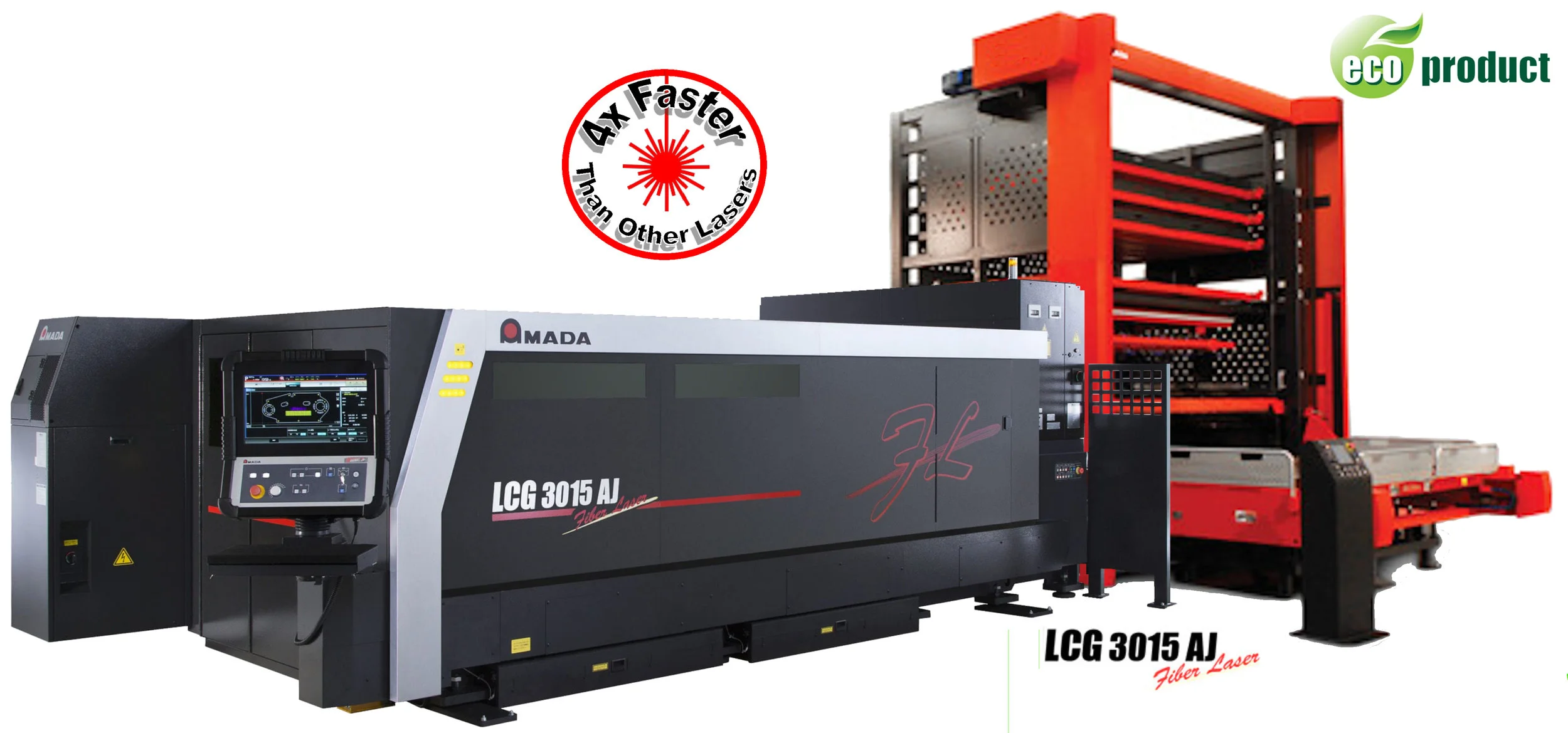

AMADA lcg3015aj FIBER OPTIC LASER w/ AUtomated material handling

The LCG3015AJ is a 6kW laser it's 3x more efficient and uses 1/3 of the electricity of a CO2 laser. It has a 60” x 120” table and can cut 3/8" mild steel, stainless steel, and aluminum. This laser is the world’s fastest linear drive laser. The LCG is engineered to produce the highest quality parts at unmatched speed while reducing operating costs and environmental waste. The LCG3015AJ has faster-cutting speeds of thin material 2 to 4 times that of comparable 4000w Co2 lasers.

- 60 x 120 max material size

- 3/8" max material thickness

- ECO friendly and more efficient

- Lights out 24/7 load and unload system

- Ever wondered how a fiber laser works find out here - How a Fiber Laser works

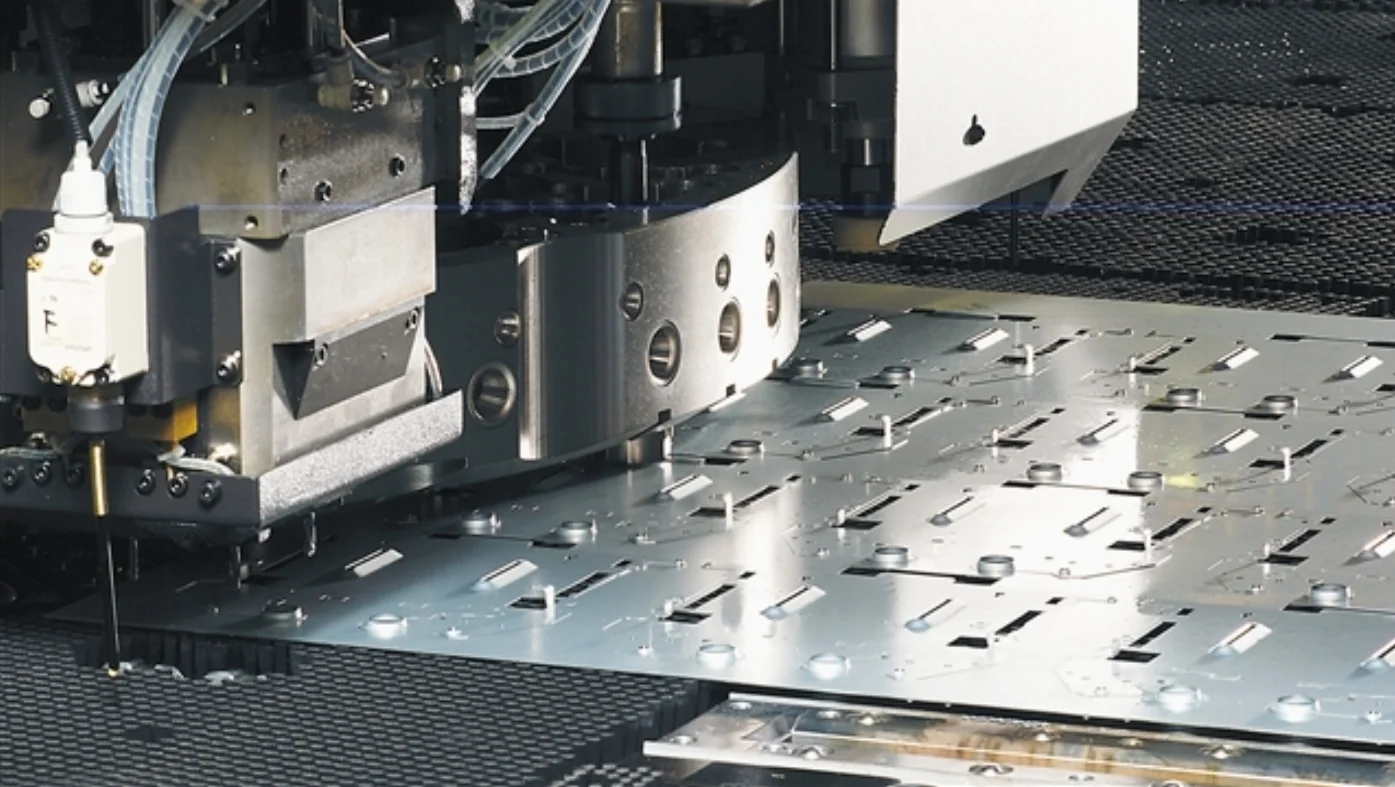

AMADA emlk 3610nt hybrid laser/turret w/automated material handling

The EMLK represents an evolution in punch/laser combination technology. The EMLK combines electric servo motors with a reliable hybrid laser motion system. The result is one of the fastest, most productive pieces of equipment we have; it delivers unequaled precision and flexibility.

- 60 x 120 max material size

- 10ga max material thickness

- 58 station turret

- automated part picking technology

- ability to form down

- Lights out 24/7 load and unload system

AMADA fomii 3015n laser

- 60 x 120 max material size

- 1/2" max material thickness

AMADA vipros king w/automated material handling

- 48x96 max material size

- 10ga max material thickness

- 58 station turret

- ability to form down

- Lights out 24/7 load and unload syste