Metal Fabrications - Engineering

When it comes to experience and engineering Pro Metal Works has you covered. Many things affect whether a product or project will stay within budget, meet schedules, and function properly. Pro Metal Works assists their customers in managing these variables in prototyping and supporting you throughout your engineering phases; so that you can address the needs of your client.

Engineering Overview

Between the owner, sales, and engineering we have over 140 years combined experience.

Advanced technology coupled with time-tested methods to furnish and engineer items from simple to marketable products.

Engineering thoroughly examines each component for production quality, functionality, and cost.

Performance in engineering, project management and communications ensures that every step in the process you are kept aware of the progress and that your part or product will meet your specifications.

We can provide to our customer's design reviews and on-site assistance in engineering, and we will make recommendations for better form fit and function in many cases.

Engineering Tool Highlights

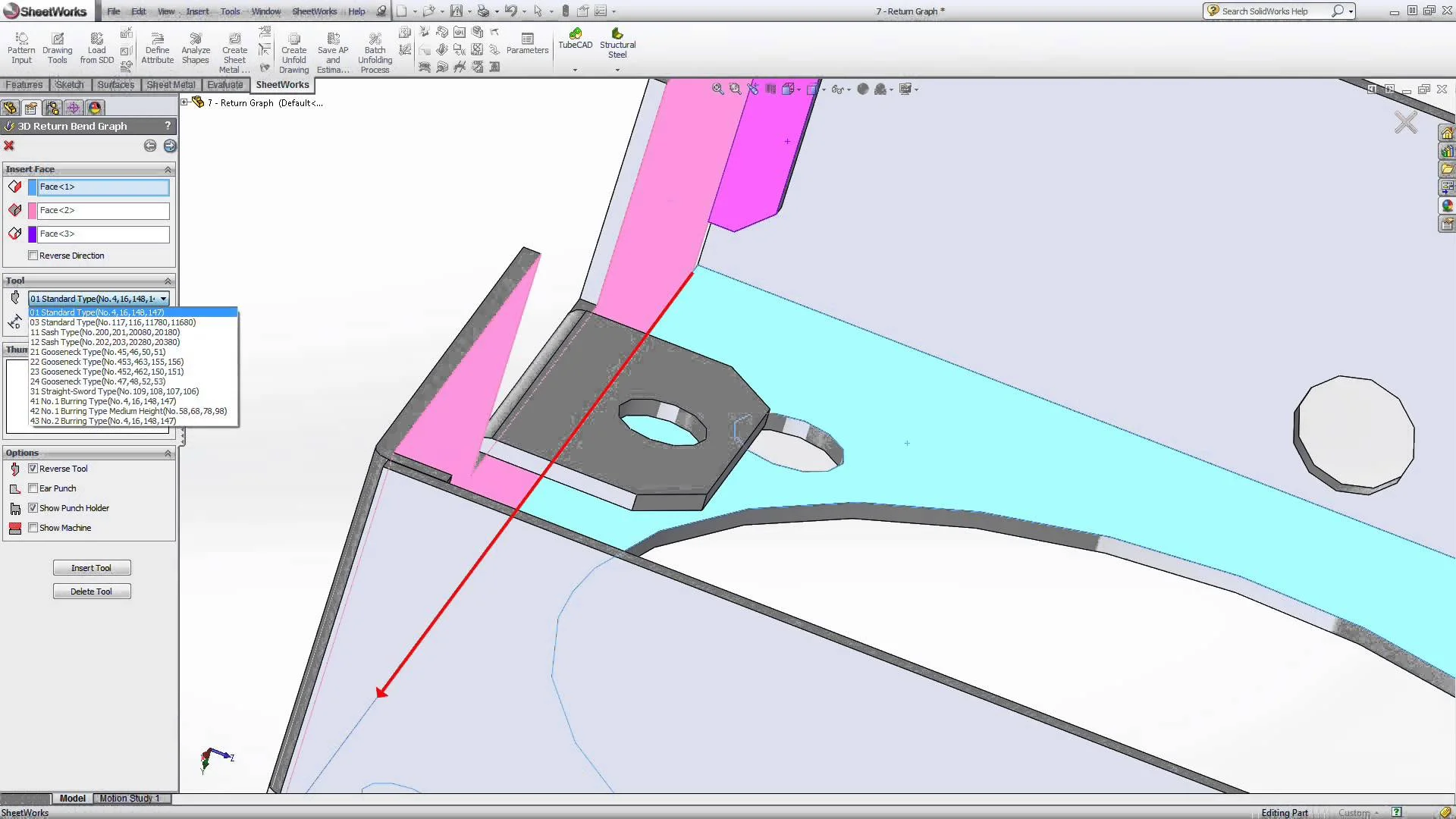

Our software allows us to Integrated sheet metal and bending into the SOLIDWORKS environment.

We're able to create precise sheet metal solid models starting from shell models, including all the necessary technological information.

Central data servers hold all engineering data and communicate to all workstations.

We're able to maintain customer design integrity through all steps of engineering development.

Automatic programming of part nesting including tool assignment, sequencing, tagging and part placement.

Optimized idle movements and turret rotations.

Virtual offline press brake programming yields efficient setups.